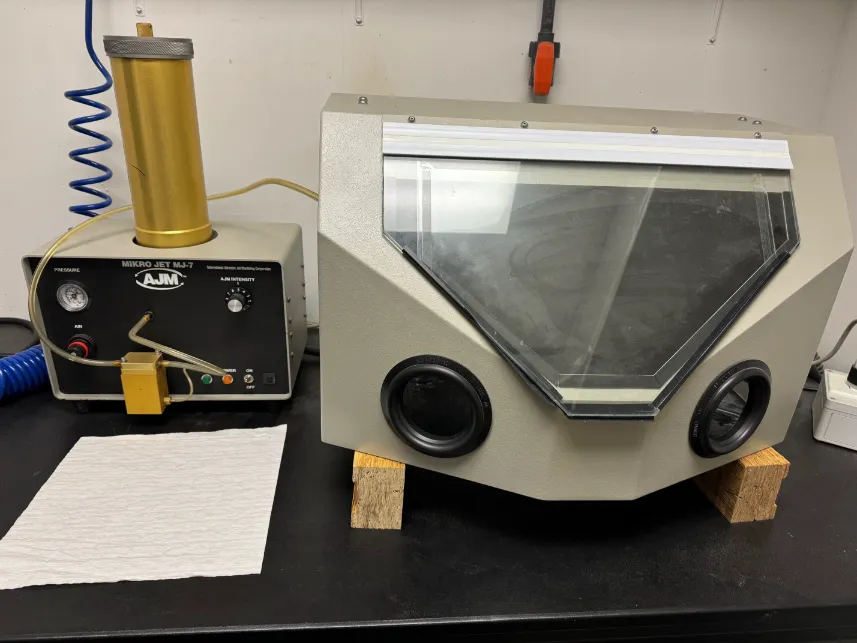

Our deburring department consists of four full-time deburring/finishing staff with 70+ combined years of experience. This experience, coupled with an understanding of machining and print reading, allows them to work hand in hand with our engineers. When only the human touch will do, our customers have come to rely on our tribal knowledge of how to reach and successfully deburr cross holes, under cuts, threads, and deep internal bores. All our manual deburring is done under the scope at 30x power. Additionally, BID employs the use of cobots, micro-blasting, and many proprietary methods to successfully deburr, polish, and finish your parts to the most demanding requirements.

Brinkman Industrial and Defense has a dedicated finishing room with four full-time deburring/finishing staff with 70+ combined years of experience. Our services include micro deburring, deburring up to 30x capabilities with Leica microscopes, glass bead/sand blast capability, and micro blast capabilities.