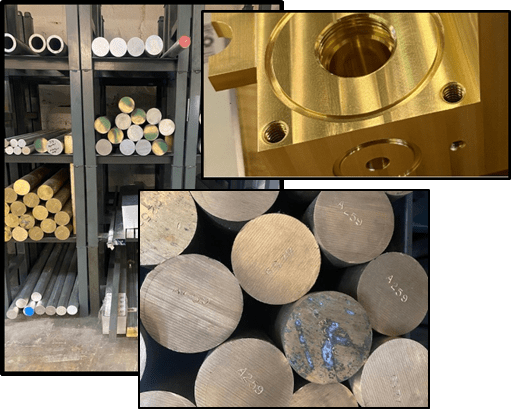

Common Materials

ALL MATERIAL LOTS ARE ASSIGNED A LOT ID FOR TRACABILITY- Aluminum

- Brass/Bronze

- Stainless Steel

- Low, Medium & High Temp Carbon Alloy Steels

- Exocitc Alloys

- Printed Additive Material

- Tool Steels

- Cast/Ductile Irons

- Polymers

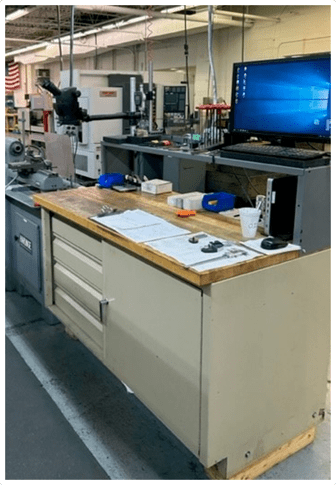

CNC Milling

Equipment:

- 1 - Mori NVX5100

- 1 - Mori DMU50

- 1 - Mori DMU50 w/ Pallet System

- 2 - Mori NHX4000 w/ Pallet Systems

- 1 - Doosan DVF 5000 w/ Pallet System

Each Machining Station has dedicated inspection equipment.

Additionally SPC collection capabilities.

Tolerances:

- Milling +/- .0002

CNC Turning

Equipment:

- 2 - Mori NL2000

- 1 - Mori NLX2000

- 1 - Mori NLX2500

- 2 - Doosan 2600SY

- 1 - Hardinge GT

Each machining station has deidicated inspection equipment.

Additionally SPC collection capabilities.

Tolerances:

- Turned Diameters +/- .0002

- Turned Lengths +/- .0004