CNC Milling

Brinkman Industrial Defense has earned a reputation as a premier CNC milling facility. We have your needs covered, whether we are machining short run highly complex parts on our Mori DMU 50 5-Axis CNC mill or complex high production on our Makino DA300 40 pallet 5-Axis CNC mill.

Our other milling capabilities include CNC horizontal and CNC vertical milling, most with automation packages for lights-out manufacturing.

CNC Turning

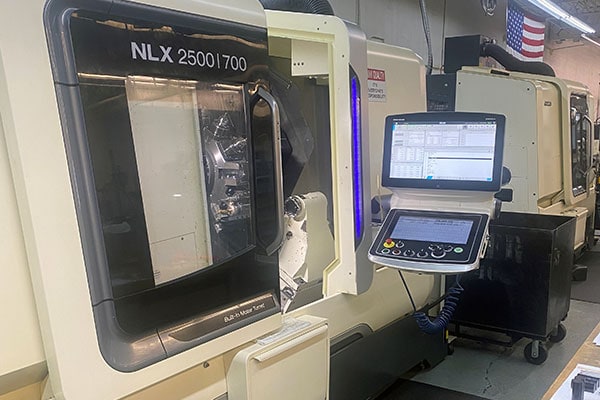

B.I.D. has earned the reputation of being a premier CNC Turning facility. From machining short run highly complex parts on our CNC Mori NLX lathes with 3-Axis and live tooling to complex high production parts on our bar fed CNC Doosan 2600 twin spindle 3-Axis lathes with live tooling, we have your tooling needs covered.

Our other turning capabilities include CNC 2-Axis lathes. All our CNC equipment is state of the art, well maintained, highly accurate.

Quality

Quality is fundamental to assuring the accuracy and ability to manufacture the best possible products. BID employs a rigorous quality control system coupled with the necessary equipment to verify part requirements. Our inspection equipment includes advanced measurement and inspection tools such as coordinate measuring machines (CMMs), laser mics, optical comparators, and profilometers to ensure components meet the specified tolerances of customer requirements.

Deburring / Finishing

Our deburring department is led by an experienced person with over 35 years of deburring and finishing experience. This experience, coupled with an understanding of machining and print reading, allows him to work hand in hand with our engineers. The result is completing much of the manual deburring in the machine. When only the human touch will do, our customers have come to rely on our tribal knowledge of how to reach and successfully deburr cross holes, under cuts, threads, and deep internal bores.